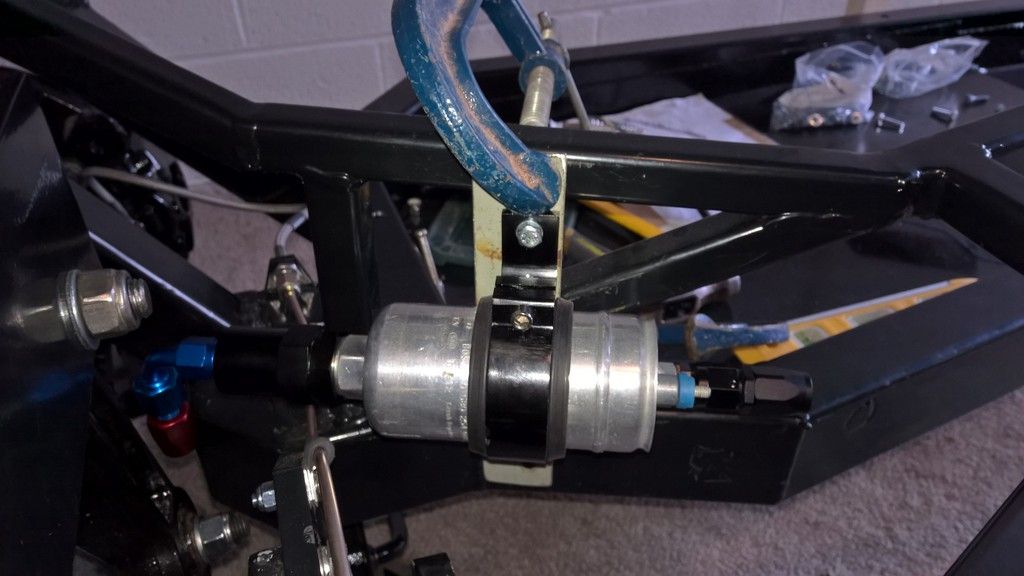

The first task was to complete the back axle setup. The speed sensor rotator had arrived from Jaguar although just as with the first one the holes didn't quite line up and it needed some small adjustments. I bought this as I needed a 2mm shim for the drivers side axle to get it to between 0 and 0.5 degree (top in) and the smallest Jag do is 3.5mm for that side.

After getting one for the other side of the car and confirming it is 2mm thick I decided it was the perfect solution. It took longer to re-level the car than it did to fit and I was soon putting the suspension into place.

Next up was to fit the radiator. The lower bracket went on easily but the lower radiator outlet fouled on the corner of the bracket.

After checking with AK this can happen and its just a case of cutting the corner of the bracket. I had to take off a reasonable amount to make it fit so I adjusted the opposite side of the bracket so it matches and looks correct.

After checking with AK this can happen and its just a case of cutting the corner of the bracket. I had to take off a reasonable amount to make it fit so I adjusted the opposite side of the bracket so it matches and looks correct.

You need two rubber gromets for the radiator to sit on which are not provided with the kit and after checking on the cobraclub forum I found a link to this part at rimmerbros . At £1.30 each it wasn't worth the effort of making my own grommet but if you are interested in this approach then Jon at AK gave me the following advice.

"You need to make two top hat shaped grommets to fit over the pegs

on the radiator , I use two different size hose, 1 x 10mm i/d hose to fit over

the peg and another piece to fit over that tube cut about 4 or 5mm thick."

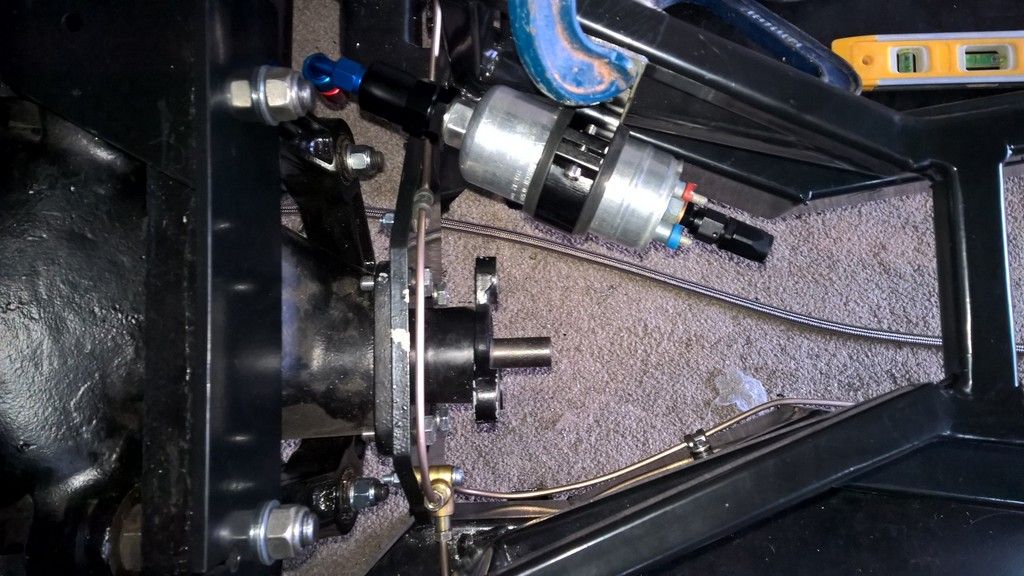

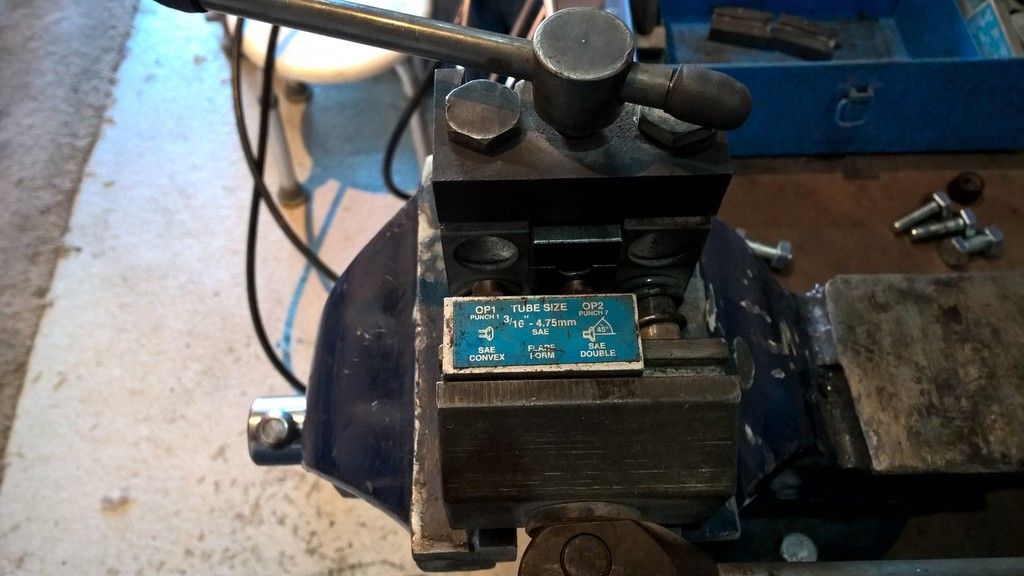

Next was to replace two M10 hex bolts in my bell housing with Allen bolts. This was because the bolt head was fouling on the housing followed by changing one of the connections on the end of my fuel line as it was also fouling on the housing (see updated Fuel lines post).

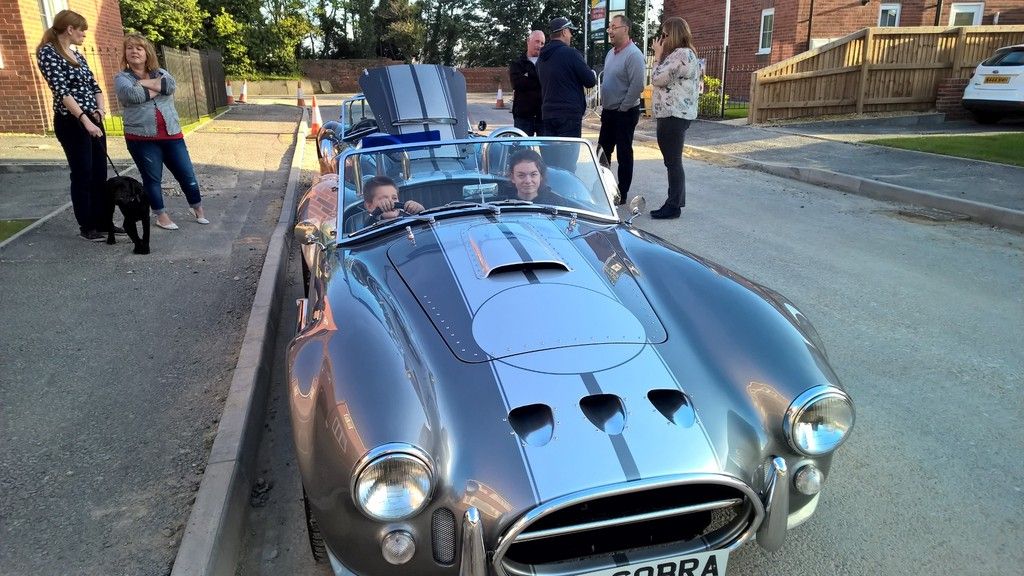

Whilst working on these tasks Si Smith arrived along with the Catherine and friends to see how I was getting on. It gave a great opportunity for the kids to see the finished article.

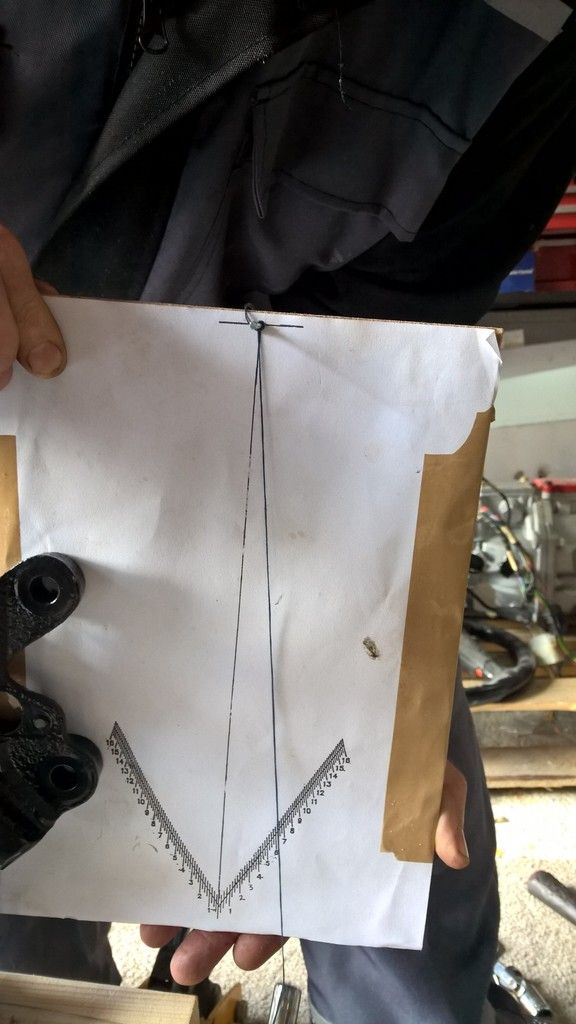

As we were discussing some of the challenges I have had they all confirmed what I had been thinking which was that my engine was sat slightly lower on one side. After measuring we confirmed this to be 5mm; a small amount but viewable to the naked eye. It appears as if the mounting brackets supplied by AK have a slightly different angle on side. This is easily adjustable and I am just waiting for a 5mm aluminium plate to arrive which I can use as a spacer. I picked this up for less than £2 on ebay.

All that is left now is to level the engine, bolt the gearbox mount, touch up the chassis with por-15 (from where I have drilled etc) and order the prop shaft and the rolling chassis is done.