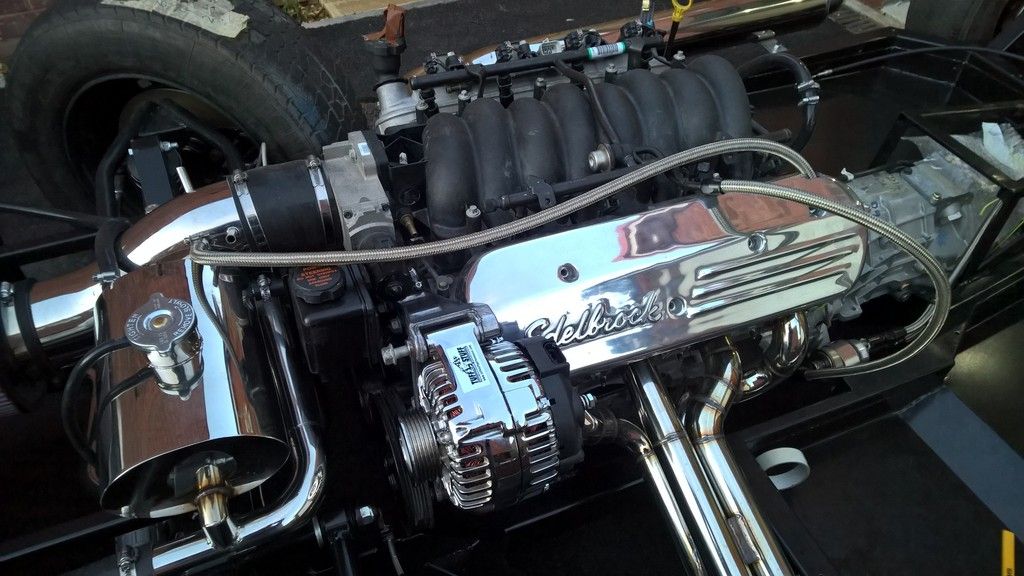

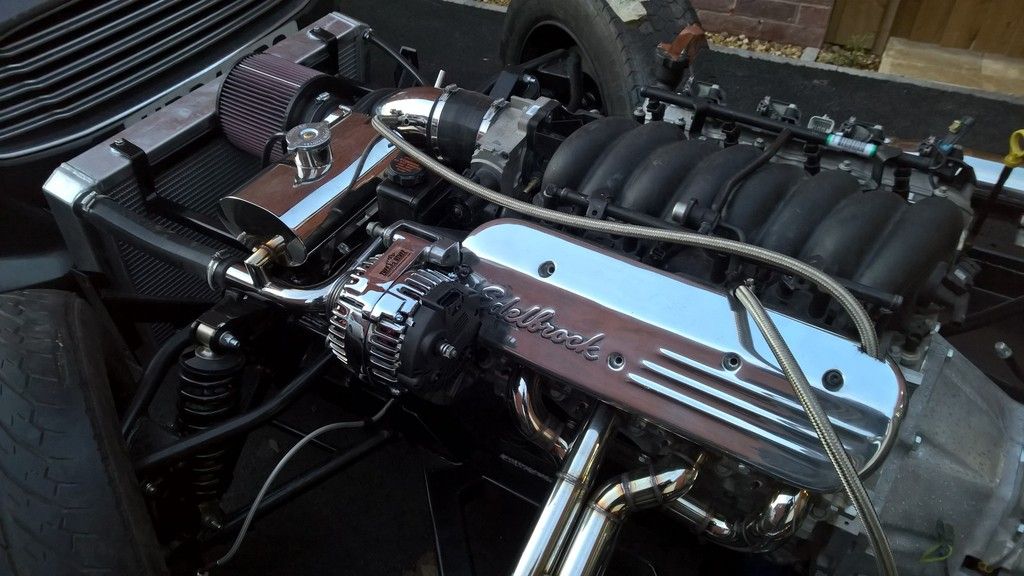

My drive belt should arrive this week and then I need a spacer for the thermostat housing as the LS6 housing when turned as AK do on the LS3 fouls on the drive belt. Once I have these I can plug in the ECU, connect to the pedal and start button and in theory it should all start up.... well see if that works out to be the case.

In the meantime I thought I would get on with another job that I realised I hadn't thought of - the radiator fan. A rather important oversight when doing the cooling system, which I had already filled with coolant. The air was a little blue when this dawned upon me.

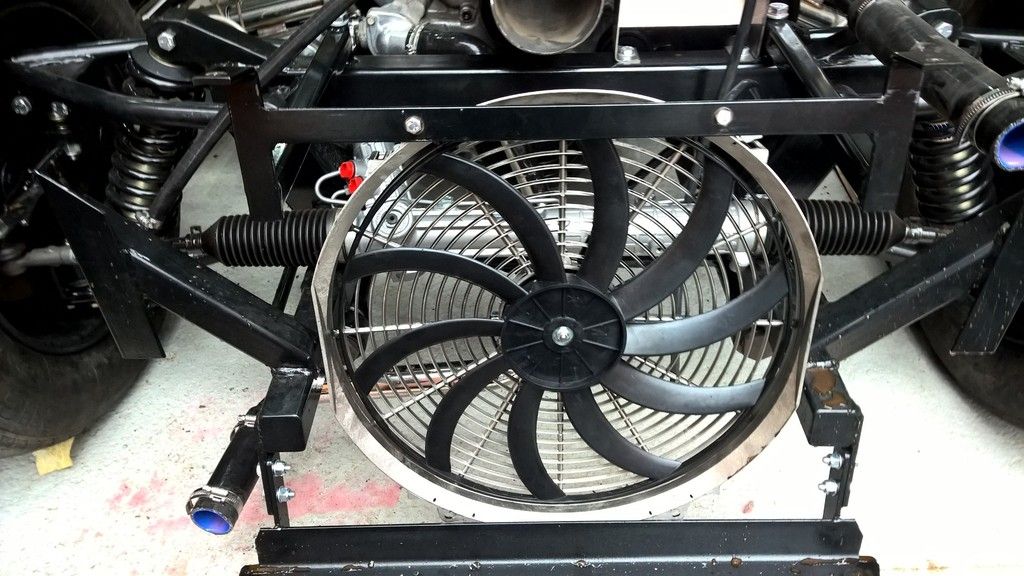

I managed to source a trimline chromed 16" fan which another cobra had in their garage. This came recommended from a different cobra owner so hopefully it will do the job.

Then - first problem!

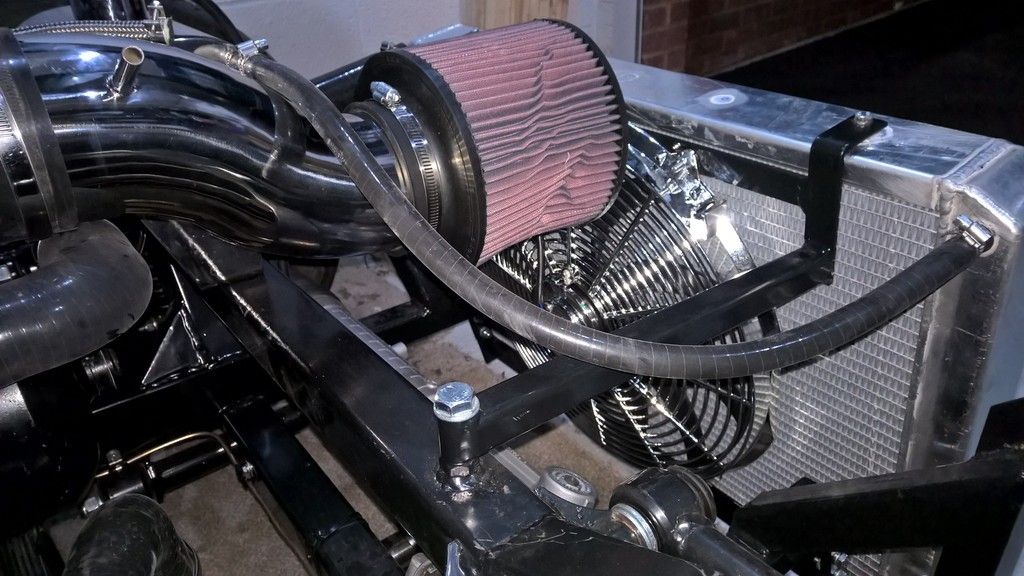

AK had fitted the air filter so close to the radiator that I couldn't offer up the fan properly so first job was to take of the air filter and stainless air intake pipe and cut 2cm of the pipe. A quick job but it felt like such a waste of good stainless steel - never mind, it had to be done.

Then - first problem!

AK had fitted the air filter so close to the radiator that I couldn't offer up the fan properly so first job was to take of the air filter and stainless air intake pipe and cut 2cm of the pipe. A quick job but it felt like such a waste of good stainless steel - never mind, it had to be done.

Once offered up I realised that the great thing about a 16" fan is that it pretty much fits between the two AK radiator brackets which means you don't have to use the ugly plastic zip bolts that most radiators use. It took just a few minutes to locate and drill the top bracket and locate the bottom fan holes but then.... second problem... the bottom bracket didn't quite reach the bracket.

Light bulb moment - I had some 100mm Wickes angle brackets and the holes lined up perfectly so I trimmed the brackets down, painted them up and then put one M6 bolt down through the radiator bracket and angle bracket (same face as the rubber grommets) and the other M6 bolt through the bracket and radiator.

To help ensure the bolts don't bottom out on speed humps I trimmed the bolts down to just passed the end of the nyloc.

Another task completed and now just to await the last couple of parts before refilling the cooling system.