Much of today was spent on the wiring in the boot. I decided to replace the wiring on the lights which was using bullet connectors with better plastic connectors. I didn't go with the weatherproof ones as its in the boot, although I have bought weather proof for the front lights.

I had a little problem with the earth on the loom not quite reaching the chassis bolt for the boot so I decided to drill a new hole right through the chassis and into the boot. The added bonus here was it should be hidden out of the way with the battery so I can box it in. Attached to this was the AK loom earth and a separate battery wire negative which went up to the earth bar shown in a previous blog. From the earth bar I then attached the battery negative, the engine negative, the fuel sender earth and the indicator earth.

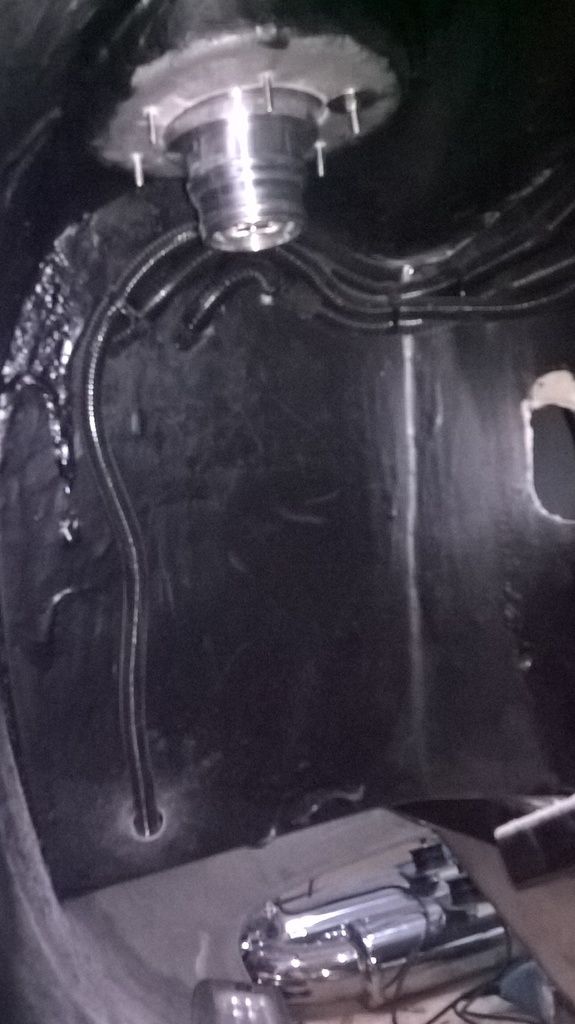

I had a little problem with the earth on the loom not quite reaching the chassis bolt for the boot so I decided to drill a new hole right through the chassis and into the boot. The added bonus here was it should be hidden out of the way with the battery so I can box it in. Attached to this was the AK loom earth and a separate battery wire negative which went up to the earth bar shown in a previous blog. From the earth bar I then attached the battery negative, the engine negative, the fuel sender earth and the indicator earth.Next was the simple job of attaching thing in place with cable ties and putting all the wires in conduit. Not a difficult task but for some reason it took ages to do.

I have also started to make the battery tray - ill post about that separately once I have completed it.

Finally, it was time to cover the boot in SilentCoat to reduce vibration, road noise and differential noise.

This leaves a much smaller list than I had yesterday. I am quite pleased with the weekends work and looking forward to getting the back end of the car finished next weekend.

- Make and fit battery tray

- Make and fit bracket to mount fog/reverse lights on nudge bar

- Fit a differential plate to protect the fuel lines