From an early stage of the build I always wanted a useful heater / cooler because, like goldilocks I like to be just the right temperature.

This meant having the controls on the dash so this meant that they needed classic design. I also wanted modern controls, variable heat and dash/windscreen adjustment.

So after hours and hours of research I came to the conclusion that I wanted the controls made by old air products show below.

Unfortunately the heater unit was too big to fit in the car so I needed a separate unit. After more research and lots of checks to ensure I could connect these controls I decided to purchase the following unit from T7 Designs.

But I still had an issue. The T7 unit was compact, also did A/C (for when the hard top is on) but didn't allow for variable adjustment on water flow and dash/windscreen position. This meant I had to go back to old air products. Luckily they provide an "upgrade" for their units which has these options. Picture below.

How to connect the three parts together?

First I needed to know how much room I had and when I offered the unit up into position it became clear the unit would have to mount sideways. This actually worked out well because this meant the unit would suck air in from the inside of the car rather than the engine bay which is an IVA fail.

I also bought some stainless steel to extend the tunnel and box in the heater, also to ensure it wasn't pulling air from in the engine bay.

After making a wooden template I realised that the plenum from Old Air wouldn't fit as it came and so adjustment was going to be required. Nothing that some time with the angle grinder wouldn't fix :-)

Sikaflex was used to fix the parts back together and to fix the plenum to the front of the T7 heater casing.

I'll come to the electrics later.

Before fitting the plenum to the heater casing I had to remove the two round connectors on the casing and then adjust it to fit the plenum. This involved cutting one side of the casing larger and blocking the other side up with liquid plastic, purchased from ebay.

Before I could actually fit the heater unit I needed to finish making the stainless box in the tunnel. This meant drilling the steel to fit the shelf.

Stainless steel is HARD to cut, HARD to bend and HARD to drill but eventually I had the first piece in place allowing the unit to be offered up, connecting the drain pipe and air pipes.

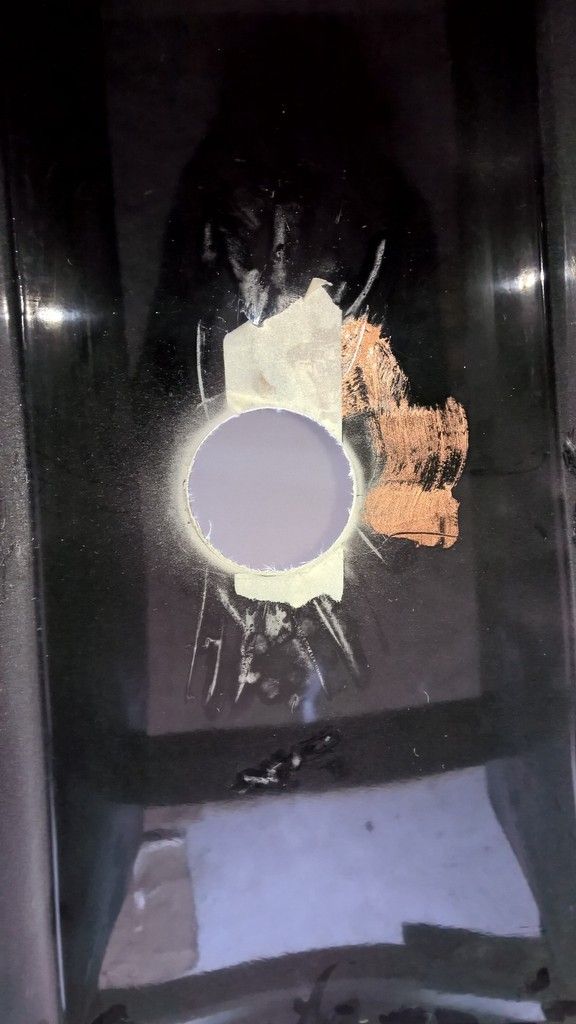

In order to ensure everything fitted I needed to cut a larger than normal hole in the body.

Then, I had to remove the stainless edgine strips AK had added in the engine bay. This is simple enough, just dill through the rivet head with a 3mm cobalt drill bit and then follow through with a 3.5 or 4mm bit to remove the rivet.

Next I needed to make a template for the front of the heater. I did this with a piece of steel and some cardboard.

Thanks to Andrew Sharples for letting me borrow his sheet metal bender. The sheet measurements was 13cm for the top and then 16cm down for the front face. 11cm is the actual top, whereas 3cm slides under the front bulkhead like so.

Then I needed to trim the edging strips AK provided as shown below.

Theres lots more to do on this. Watch out for part 2 coming soon.

Many people complain about vibration in the roll hoops so I have fitted some silent coat to the underside of the brackets as removing vibration is one of its key features.

Many people complain about vibration in the roll hoops so I have fitted some silent coat to the underside of the brackets as removing vibration is one of its key features.