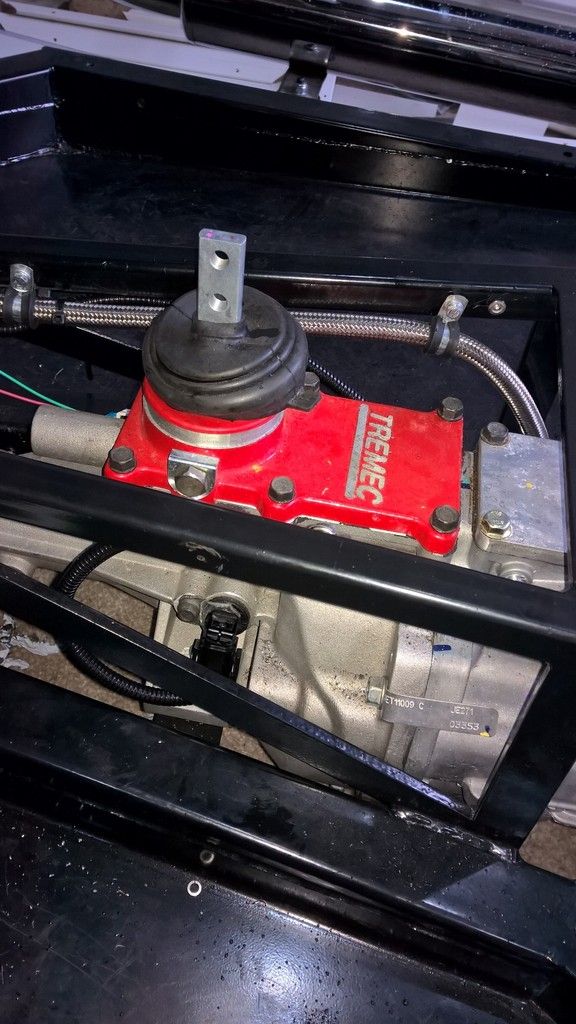

Further, if you have a Tremec T56 Magnum gearbox it comes with two speed sensor locations (mechanical and electronic).

I have chosen to go with the electronic version as you can easily buy a blanking plate for the mechanical sensor and an installation kit that has the other sensors in it.

NOTE: there are different electronic speed sensors (VSS sensor) depending on the T56 version you will have bought. I fell foul of this and had to re-order the correct sensor.

I ended purchasing the parts from differing places but I've since found that bowler transmissions in the USA do all the parts needed:

I ended purchasing the parts from differing places but I've since found that bowler transmissions in the USA do all the parts needed:https://bowlertransmissions.com/p/564/t-56-magnum-installation-set-includes-vss-reverse-lockout-reverse-light

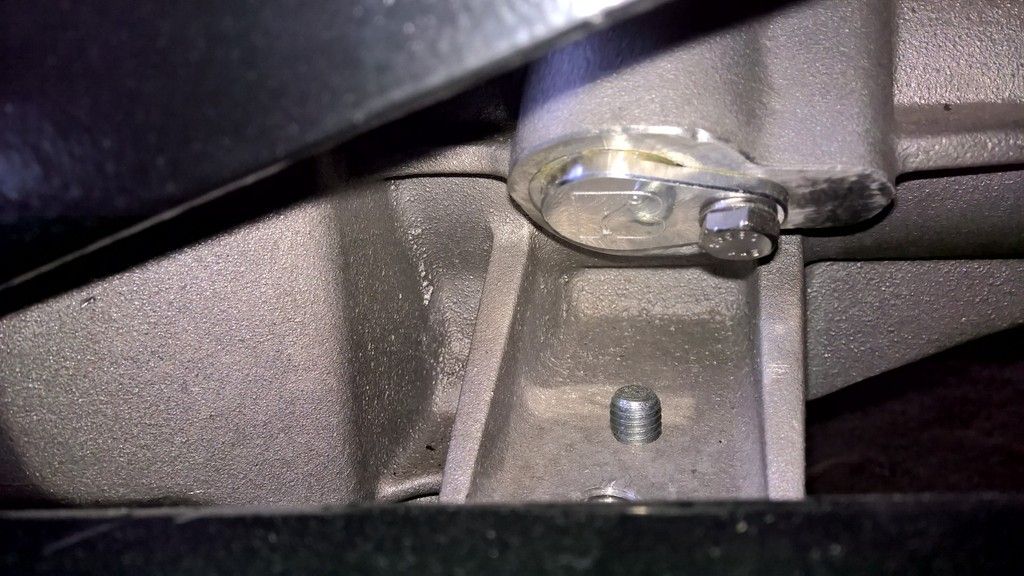

Finally you will need a 1/4"UNC x 1/2" bolt to secure the blanking plate to the transmission, which I got from Kays on ebay.

First fit the blanking plate, which is on the left hand side of the gearbox (if your looking down from above with the engine in front of you).

Next install the reverse lockout pigtail which goes on the sensor to the rear of the gearbox near the shifter.

Next install the reverse lockout pigtail which goes on the sensor to the rear of the gearbox near the shifter.There is only about 6 inches of wire on each of the pigtails so I extended them using the same colour wires purchased of ebay. There was enough wire added to get them behind the dash when the body is fitted, hopefully making the future wiring job easier. Just for good measure I labelled each set of wires with some cheap labels bought from ebay.

The crimp connectors I bought don't seem to work well so I bought a cheap soldering kit instead and soldered them together.

This might seem like a daunting task but you can learn to do anything on youtube these days and I found its actually quite easy to do.

In order to activate the solenoid and allow reverse to be selected I also purchased the following product from Accutech. Basically, its designed for the T56 and will activate the solenoid when the car drops below 5mph. People might advise you that you can force the gearbox into reverse without this but it is not recommended by Tremec and is designed to allow access to reverse in an emergency, not for day to day use.

In order to activate the solenoid and allow reverse to be selected I also purchased the following product from Accutech. Basically, its designed for the T56 and will activate the solenoid when the car drops below 5mph. People might advise you that you can force the gearbox into reverse without this but it is not recommended by Tremec and is designed to allow access to reverse in an emergency, not for day to day use.Next up was the electronic speed sensor which is located on the right hand side of the gearbox below the shifter.

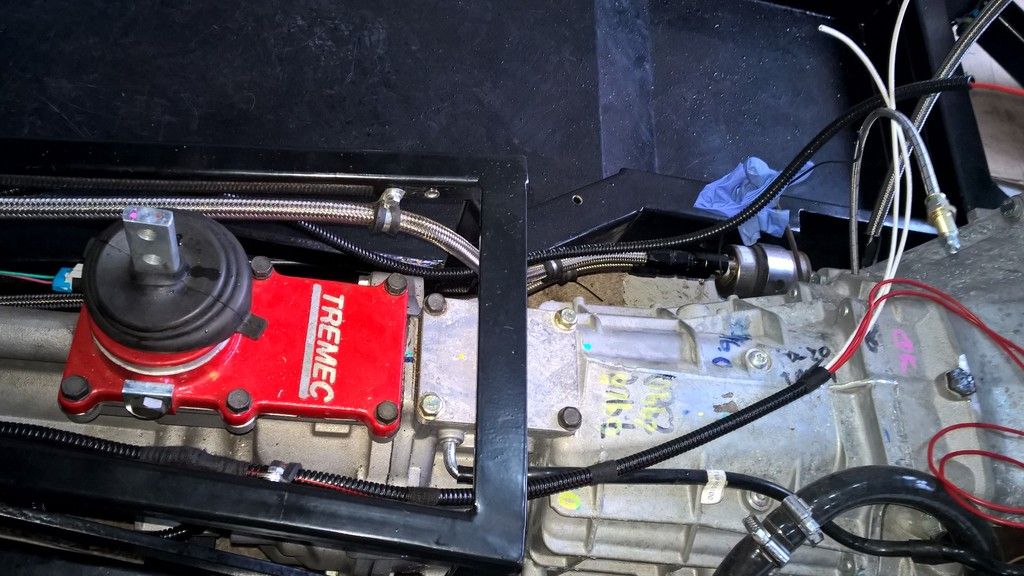

All of the wiring has been placed inside 10mm loom conduit to ensure they are protected from damage. 5mm Rivnuts were added to the tunnel frame so that rubber lined P-clips could be used to secure the conduit.

Finally, connect the reverse light pigtail, which, perhaps surprisingly makes the reverse lights come on when reverse gear is selected. This sensor already has a small amount of wire attached so I used one of the mounting "ears" on the gearbox to secure the wire with a p-clip and 6mm bolt.

As stated earlier in the post, all the wires have been extended forward to allow easy routing behind the dash when the body goes on. I am almost at the point where the chassis is ready to accept the body. There is just a small job to secure part of the fuel line which I'll hopefully get to next week.

The picture below shows the extended wires and conduit.